SELENIUM, element 34, presents a sample preparation challenge, as outlined below by certified chemist Wieland Hopfe, application consultant for Fritsch.

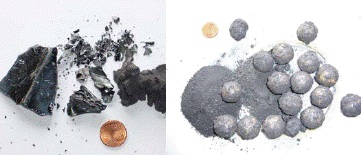

Before and after: metallic selenium and the comminuted sample

Selenium is one of the less commonly known elements, appearing on the periodic table immediately below sulphur. It is an essential trace element for human health, and is integrated by the body in the 21st amino acid, but is also a toxin. The comminution of selenium therefore demands particular caution.

The material has a number of unusual properties. At temperatures over 60C it exhibits a glassy appearance, and above 80C it forms a more stable grey semi-metallic appearance, similar to the native metal found in selenium ores.

The sample under consideration here was ultra-pure, metallic in appearance, and was to be prepared for further analysis by being reduced to sufficiently small particles.

The Pulverisette 6 planetary-mono mill was equipped with a 250ml zirconium oxide grinding bowl and 20mm grinding balls (15 in number). Fritsch technical documents recommend a maximum feed size of 10mm, although in this case the pieces were clearly larger than this. No system could be found to reduce the size of these chunks without causing contamination of the sample, and so these pieces went forward for processing.

After five minutes in the Pulverisette at a maximum rotational speed of 650rpm, the sample was assessed. This was found to consist of a fine powder with a number of larger particles. These larger pieces were removed (presumably by sieving- Ed) and the remaining sample was ground further.

After a total of 11 minutes, the material was ground to a sufficient fineness that the required representative sample of 1g could be obtained.