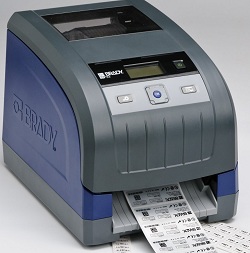

A NEW printing system for laboratory labels uses drop-in supplies that make it possible to change materials in just 20 seconds. The Brady BBP33 label printer needs no adjustment or calibration when switching label type.

BBP33 lab label printer from Brady can change label medium in seconds

Brady says the new label printer was built for users who need frequent material changeovers, and the BBP33 also helps to save costs by eliminating wasted blank labels because it prints on the first label of a roll.

Hilde De Swerdt, a marketing manager at Brady, says: “We have reduced setup time to an absolute minimum, so customers who regularly change materials in their printer will love this”.

The printer handles a wide range of die-cut labels for product, wire, and laboratory identification, as well as a full range of safety and facility label materials.

In the laboratory, it will eliminate the effort in labelling samples for traceability and identification, says the company, allowing laboratory specialists to focus on more important tasks. BBP33 works with materials and label sizes specifically developed for the laboratory environment.